Magnetic

Materials

閉じる

Search

=Customer’s requirements =

“Some customers have requested that they want to increase the magnetic force slightly, but you have not been able to do so, because of the limited quantities and the cost burden of making the molds…”

“If you use such as an isotropic NdFeB magnet material, we can achieve the magnetic force required by the customer.

However, if we increase the amount of resin, there will be a large shrinkage after molding and you have to make a new mold…”

“You are wondering if you can enhance the magnet force a little more than current product with the same size and without new mold or major modifications of mold…”

Is there a magnet material that can be used to increase the magnetic force a little more than the current product in the same dimensions without new molds or or major modifications?

Wellmax™-S4 is an ideal injection molding magnet material for applications in case you want a little better performance than ferrite magnets.

Wellmax™-S4 product is an injection molding material that replaced part of the anisotropic ferrite magnet powder with SmFeN (samarium iron-nitrogen) magnet powder.

Sumitomo Metal Mining produces Wellmax™-S4-series that have 24kJ/m3(3MGOe) to 56kJ/m3(7MGOe) maximum magnetic properties with available in 8~16kJ/m3(1 to 2MGOe) increments.

If you wish own control of properties, you can blend some magnet pellets in hopper (i.e. called integral blending).

For the case of lower content of SmFeN magnet powder, you can product requested magnet with same mold only to use Wellmax™-S4*1.

Note*1: You may also need new mold parts in case of lower magnetic field to align the magnet powder.

In addition, the magnet used Wellmax™-S4 is less likely to rust than NdFeB magnet and you can handle the abrasion of mold and rust countermeasures equivalent to ferrite magnet.*2

Note*2: When SmFeN content is high, new orientation designs and anti-rust measures may be required.

Demagnetization curve

If you take us current magnetic circuit of mold and properties of magnet material, we can suggest you that how enhancing surface magnetic flux with our simulation technique based on our abundant knowledge and experience.

The functions realized through Wellmax™ to “enhance” can also be applied in other fields.

Do you want to realize your imagination with our Wellmax™?

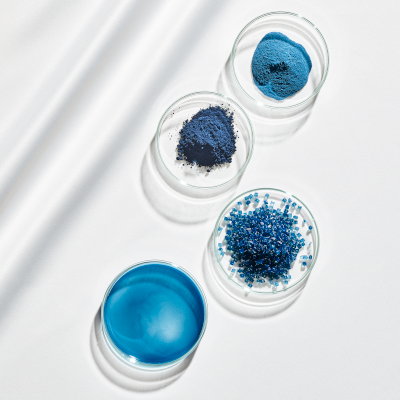

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PA magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

Ready to get started? Contact us to talk about your requirements.

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)