table of contents

Controls the bluish tint without reducing the strength of near-infrared absorption

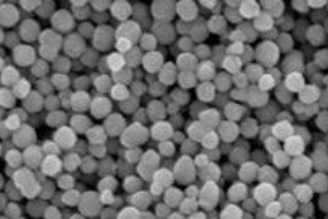

Sumitomo Metal Mining Co., Ltd. has developed a new near-infrared shielding material with a neutral color using Cs-doped polytungstate (CPT) material. Since two decades ago we have manufactured and provided nanoparticles of proprietary LaB6 (lanthanum hexaboride) and CWO™ (cesium-doped tungsten oxide) as near-infrared shielding materials. Near-infrared shielding materials are used for various types of glass coatings, laminated glasses, and plastic glasses in automotive and general architectural windows. However, there exist weak greenish and bluish tints in LaB6 and CWO™ transparent filters, respectively, that are desired removed to a colorless tone like ITO (tin-doped indium oxide) while maintaining a stronger near-infrared absorption than ITO.

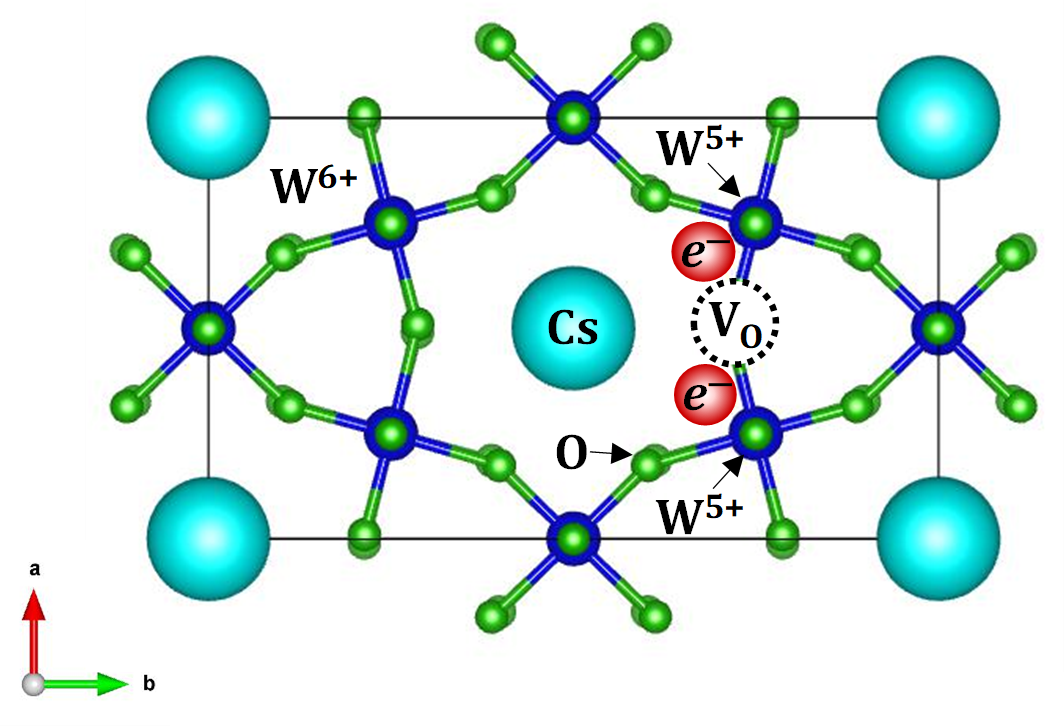

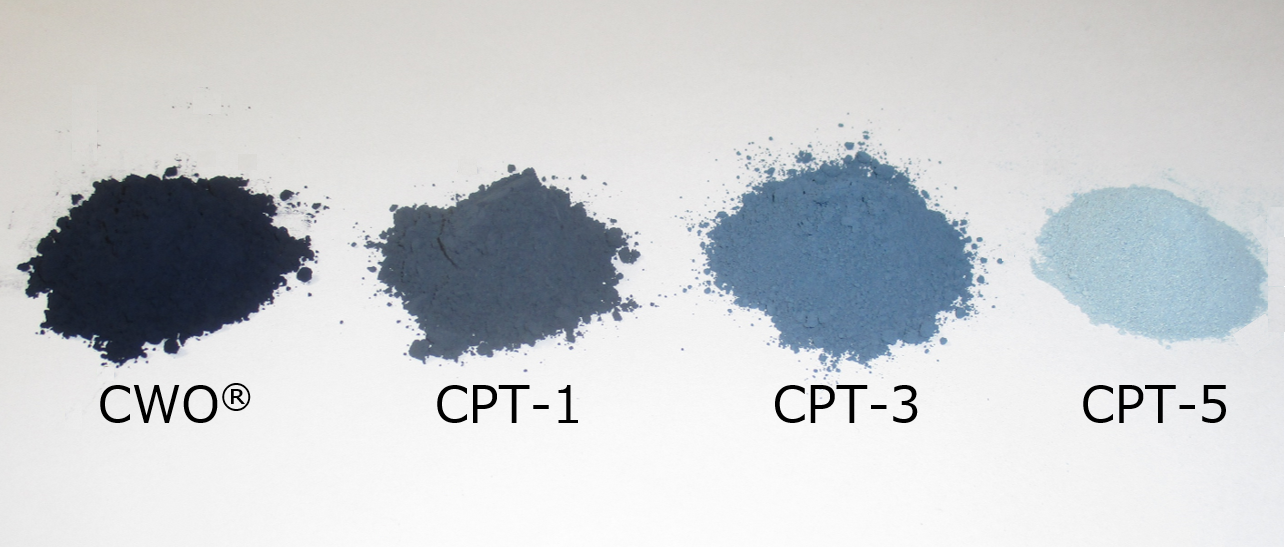

We have herein acquired a new technology that allows the blue level to be controlled between those of CWO™ and ITO without reducing the high strength of near-infrared absorption by developing CPT materials with an orthorhombic or trigonal crystal structure in contrast to the hexagonal CWO™.

A part of this development was published as a paper in the Royal Chemical Society’s scientific journal, RSC Advances. Additionally, major parts of the CPT materials will be published separately.

As a technological countermeasure to the global warming that has steadily progressed and would cause an increasing hotness in our future, Sumitomo Metal Mining Co., Ltd. has been developing near-infrared (NIR) shielding filters that cut heat waves (NIR light) in sunlight.

To date, we have developed a unique material of CWO™ (cesium-doped tungsten oxide), which nanoparticles provide the highest quality solar filter in terms of visual brightness and high shield efficiency of NIR light. CWO™ is mainly used for various windows in automobiles, houses and buildings.

CWO™ is a NIR-shielding filter with high visible light transparency, but is accompanied by a slight bluish tint.

There has been a previous request to completely eliminate this blue tint. A material that meets this demand is CPT (Cs-doped polytungsten) being released this time.

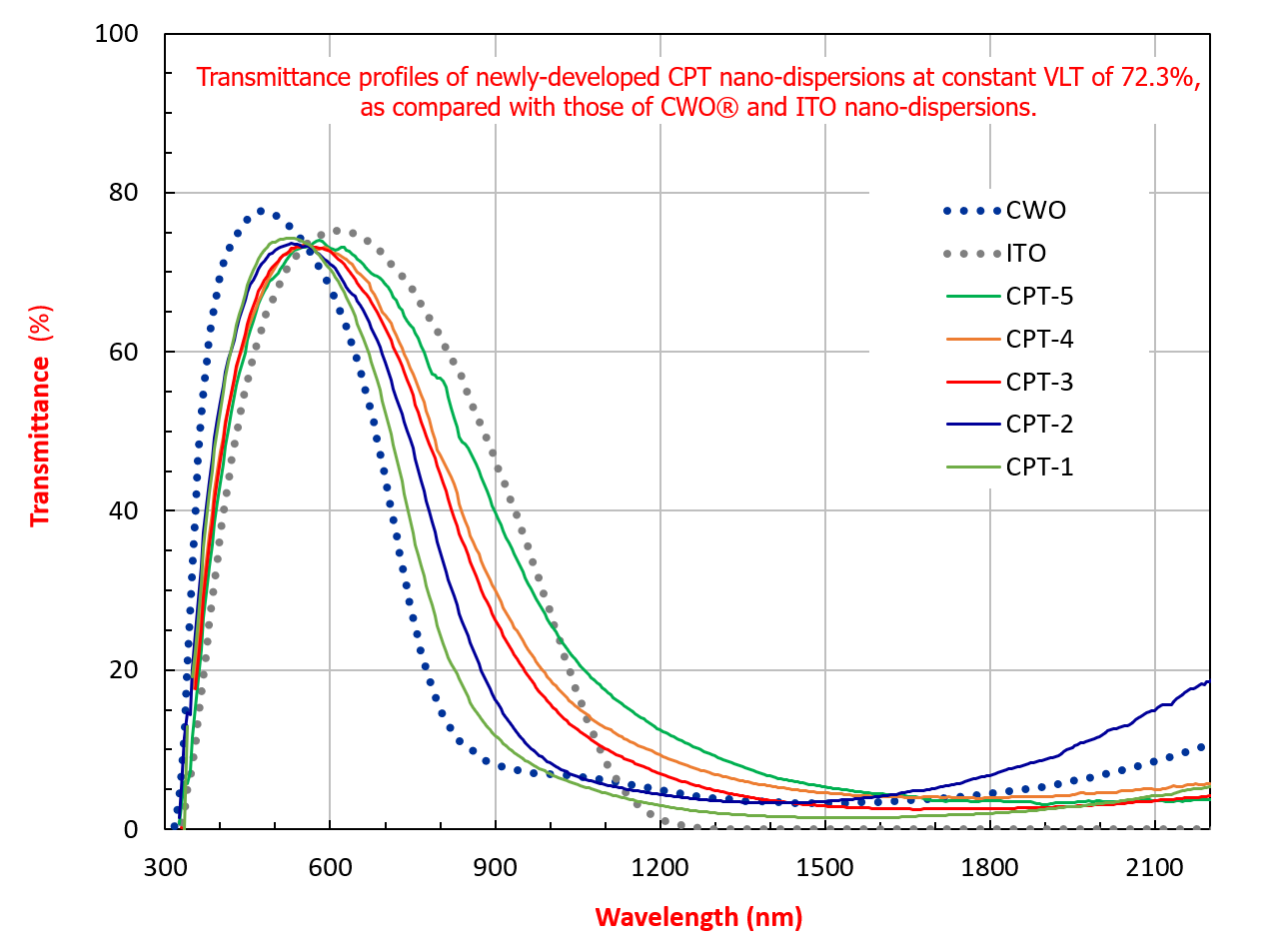

The extent to how much the color is neutralized is shown in the transmission profiles of nanoparticles dispersion filters in Fig. 1.

Fig. 1

For fair comparison this figure plots the transmission profiles of materials under constant (72.3%) visible light transmittance (VLT). ITO is known as a colorless transparent material. Since the transmittance at the visible wavelengths is transmitted evenly with respect to the human eye’s visual sensitivity curve, it looks colorless. On the other hand, CWO™ has a relatively high transmittance in blue and low transmittance in red because it shields near visible light in the near infrared. For this reason, the CWO™ filter becomes a bluish membrane even if it is transparent.

The CPTs developed shown in CPT-1~CPT-5 have profiles in between CWO™ and ITO. In other words, as indicated by the red arrows, the transmittance of blue light at 400 nm drops significantly as compared to CWO™. On the contrary, the transmittance of red light at 720 nm increases greatly. Therefore, the color of the CPT filter looks more neutral. The degree of neutral color can be chosen freely, from the bluish CWO™ to the colorless ITO.

On the other hand, the transmittance of CPT drops greatly in the near infrared wavelengths, indicating the strong absorption of NIR light. Moreover, even if the degree of neutral color is changed, the amount of NIR absorption does not change just by shifting the location of the absorption peak (transmission bottom) among samples, (although, the thermal effect changes with the peak wavelength). This effect is fundamentally different from that given by diluting CWO™ dispersions. Color changes of the presently developed CPT-1~CPT-5 is based on the controlled difference in microstructure and electronic structure.

Why can this effect be obtained?

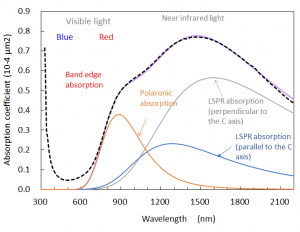

To understand the color, it is necessary to know the absorption coefficient of a material. Fig. 2 shows the experimental (dotted line) and calculated (solid lines) CWO™ absorption coefficients.

Fig. 2

CWO™ has a very small absorption coefficient at the visible wavelengths from 380nm to 780nm. However, at the blue and red wavelengths at both ends, the absorption becomes stronger, and the principle behind each is different.

Absorption of blue wavelengths occurs by the electronic band-edge transition in the material. The band-edge transition occurs when electrons in the valence band of a material are excited to vacant orbitals in the conduction band. Therefore, the narrower the band gap, the smaller the energy of excitation and the greater the absorption of blue wavelengths. We have achieved this using a CPT material with a slightly smaller bandgap than CWO™.

On the other hand, the red-wavelength absorption is caused by the localized surface plasmon resonance (LSPR) and polaronic absorption. Because CWO™ has a hexagonal crystal structure, LSPR resonant wavelengths and relaxation constant are different in directions parallel and perpendicular to the c-axis. The relative involvement of polaron and plasmon absorptions varies with the structure of the material per se as well as the size, shape, and distribution of the scattered nanoparticles, and other factors. Therefore, both the polaron and plasmon absorptions are important. If the absorption wavelengths of both are shifted toward longer wavelengths, the absorption of red light decreases, so the color shifts toward neutrality. LSPR wavelengths depend on the number and effective mass of resonant electrons. On the other hand, the polaronic absorption is caused by the excitation of localized electrons trapped by W ions, so that the absorption wavelength can be controlled by the polaron density, i.e., oxygen vacancy concentration. In this way, we were able to shift the NIR absorption to longer wavelengths and increase the transmittance of red light mainly by reducing the number of resonant electrons and polaron concentration to slightly less than CWO™.

Appendix

Innovations in materials will be made little by little. The CPT material shown here greatly improves the blue tone of the membrane but does not completely render it colorless. For perfect achromatization, a square transmittance profile with visible light is ideal, whereas for particulate dispersion filters, this realization is in principle constrained by the relaxation phenomenon of electrons. In CWO™ and CPT materials, there seems to be little additional margin in permeability and shielding that can actually be obtained as a feasible particulate dispersion filter. The limits of transparency and NIR shielding that can be obtained as fine particle dispersion filters, including general materials, are very close to each other, but Sumitomo Metal Mining Co., Ltd. will continue to pursue this.

1. Satoshi Yoshio, Masao Wakabayashi and Kenji Adachi, “Cesium polytungstates with blue-tint-tunable near-infrared absorption”, RSC Advances, Vol.10, pp. 10491-10501 (2020)

2. K. Machida, M. Okada, K. Adachi, “Excitations of free and localized electrons at nearby energies in reduced cesium tungsten bronze nanocrystals”, Journal of Applied Physics, Vol. 125, p. 103103 (2019)

Take part in X-MINING Contact Us

Ready to get started? Contact us to talk about your requirements.

X-MINING provides updates on SMM's material products and information on participating in events. Please register.

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)