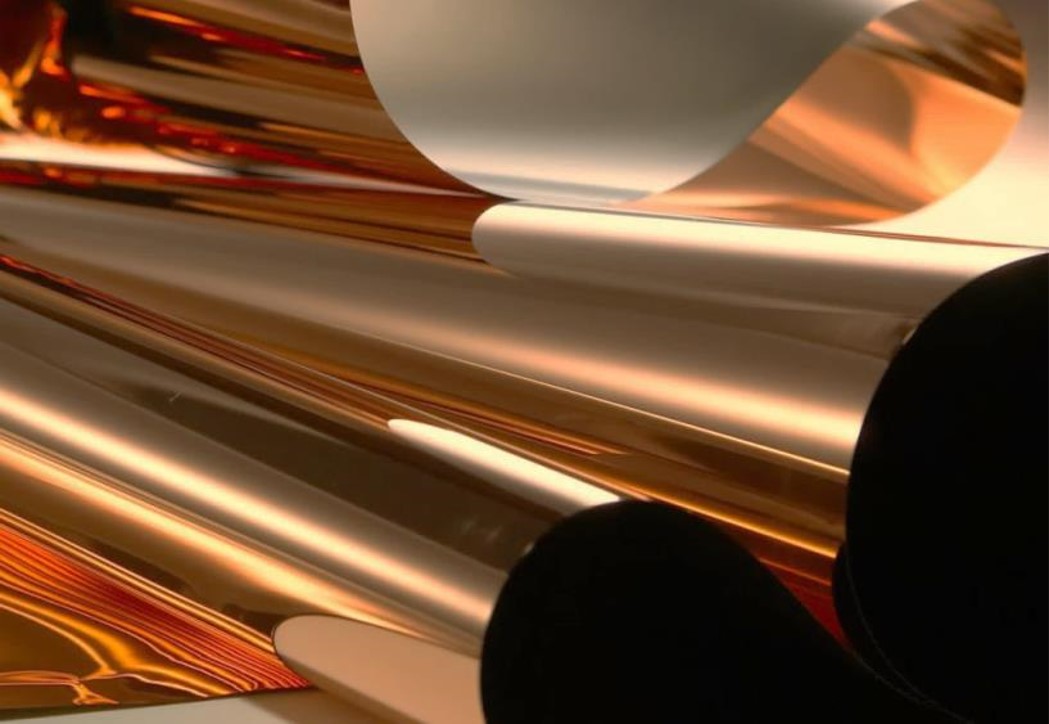

Prevent

Oxidation of copper

閉じる

Search

Excellent oxidation resistance in air despite fine copper powder.

Learn more

UCP-030N starts shrinking from a low temperature close to 210 degrees.

Learn more

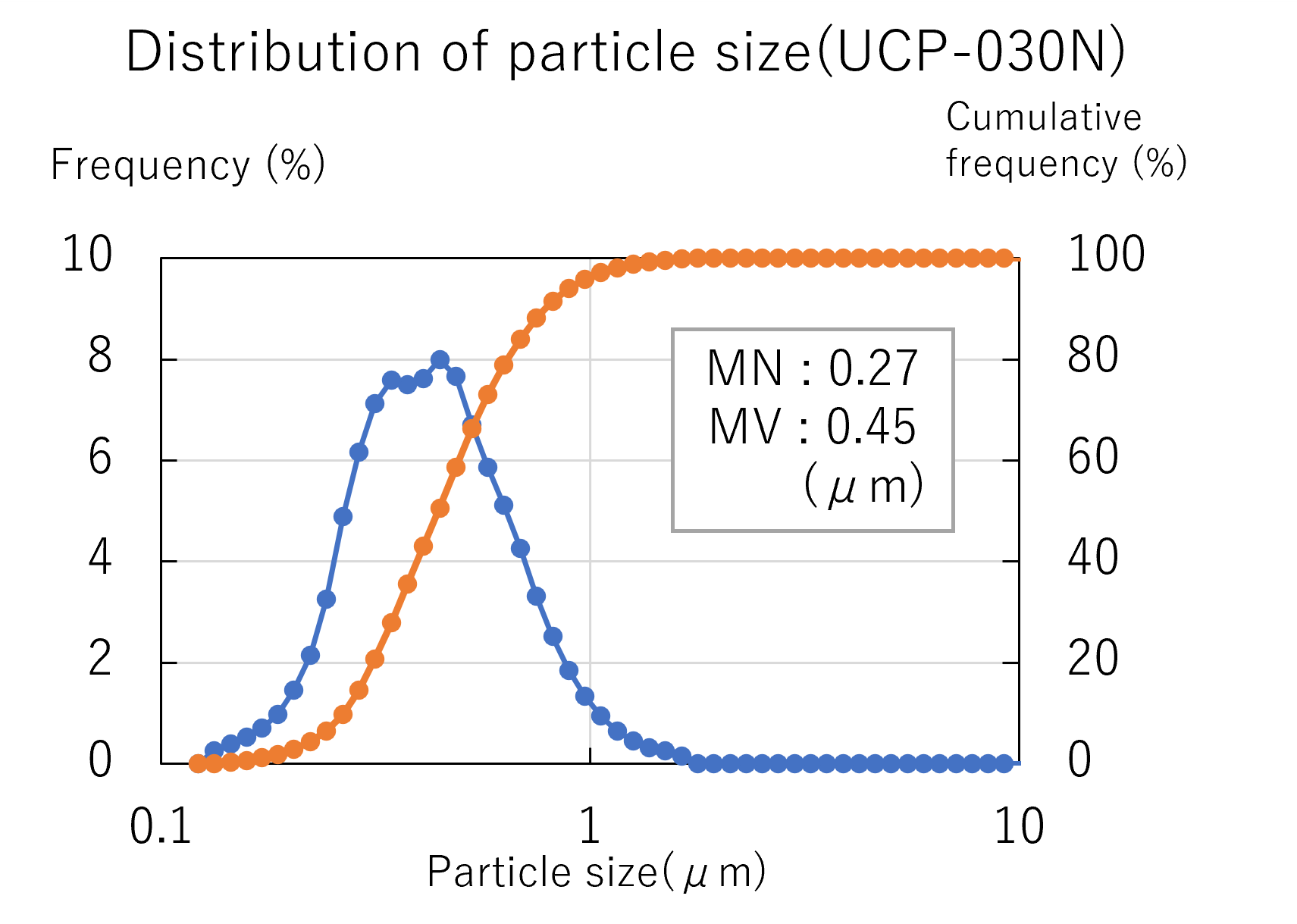

SMM's unique wet synthesis method, submicron powder with sharp distribution.

Learn more

Sumitomo Metal Mining's fine copper powders (UCP series) have a narrow particle size distribution derived from a unique wet process, and sintering begins at a significantly lower temperature than the melting point of copper through particle bonding. Furthermore, by a proprietary surface treatment, this copper powder is easy to handle and not easily change its sintering characteristics even in the atmosphere at room temperature up to 200°C. In recent years, there has been a demand for the development of copper powders that can sinter at temperatures suitable for components with low heat resistance, such as plastic substrates. Generally, reducing the sintering temperature can be achieved by refining the particle size; however, this also makes the copper powder easier to oxidation, harder to handle. Against this background, Sumitomo Metal Mining has developed fine copper powders with particle sizes of 100nm, 200nm, and 300nm, balancing ease of handling as a powder and low-temperature sintering properties using unique wet synthesis. By offering a wide range of fine particle sizes, we aim to accelerate development speed for our customers. Additionally, by leveraging the unique properties of fine particles, we realize performance improvements not only in the field of electronic materials, such as copper's antibacterial materials but also in other sectors.

Please use the registration form below to download materials related to this graph.

Overview

UCP-030N

| Developed Product lineup | UCP-030N | UCP-020N | UCP-020N2 | UCP-010N |

|---|---|---|---|---|

| SEM Average particle size(μm) | 0.26 | 0.21 | 0.21 | 0.09 |

| Specific surface area(m2/g) | 2.59 | 3.14 | 3.15 | 7.83 |

| O(%) | 0.63 | 0.44 | 0.70 | 1.4 |

| C(%) | 0.38 | 0.26 | 0.53 | 0.59 |

*The average SEM particle size and specific surface area values are representative.

Anticipated applications: conductive materials, electromagnetic shielding materials, conductive fillers, antibacterial materials.

Fine copper powder can use as conductive fillers for paste, ink, and functional resin.

Specific applications using these materials include electrodes, conductive adhesives (bonding materials), via hole fillers, and printed electronics wiring materials.

In addition, it can be used as a catalyst. In recent years, application in antimicrobial materials is also getting attention.

Electrode form by copper poses a variety of challenges, such as aggregation, lowering sintering temperature, , and maintaining quality such as oxidation resistance.

Our fine copper powder (UCP series) ,a finer and sharper particle size distribution than ordinary atomized copper powder produced by the atomization method, begins sintering at a lower temperature than atomized copper powder.

Our fine copper powder also can be used as a sintering additive to lower the sintering temperature in combination with other copper powders as well as independently.

Furthermore, our fine copper powder has excellent oxidation resistance despite its fine size, because of its special surface treatment, and will be possible to improve the stability and the dispersibility in an organic solvent or resin.

If you have some trouble with aggregation or dispersion of copper powder in the paste forming smooth and thin copper electrode films, we hope you will consider our fine copper powder as one of the solutions.

Use case about “Low Temperature Sintering to Form Copper Electrodes” are introduced here.

Our UCP-030N fine copper powder has excellent oxidation resistance and low-temperature sintering properties, making it suitable for metal filler in conductive paste/ink and sintering paste for die attach applications. Copper powder is also used in powder metallurgy and antimicrobial applications.

Our UCP-030N fine-grained copper powder is a low-temperature sintered copper powder characterized by its uniform particle size. By combining it with other copper powders, it is possible to increase packing density, lower sintering temperatures, and improve other properties.

No. Our UCP-030N can be easily dispersed in polar solvents such as water.

Overview

UCP-030N

Ready to get started? Contact us to talk about your requirements.

X-MINING provides updates on SMM's material products and information on participating in events. Please register.

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)