Magnetic

Materials

閉じる

Search

=Customer’s requirements =

“You are currently producing motors that assembled NdFeB (neodymium iron boron) compression bonded magnets with yokes or shafts by adhesives. The adhesive is applied and the shaft is inserted by an automated machine in the company, but there are problems such as uneven application and adhesive overflow, motor operation failure due to spinning of the shaft, and poor appearance in the process that results in the shaft being discarded with the shaft still attached.”

“If the gluing process is done by hand, you can reduce defects by checking the appearance of the gluing and wiping off the adhesive, but considering that labor costs are rising every year, you would like to eliminate the manual process. In addition, some clearance is required to smoothly insert the shaft into the magnet, and this clearance also causes overhanging of adhesives and vibration during motor rotation.”

What a solution to solve at once and have the same performance as NdFeB compressive isotropic bonded magnets?

Sumitomo Metal Mining’s Wellmax™-S3/S5 products are materials that can be injection molded to produce magnets with the same or better performance than NdFeB compression molded magnets. With injection molding materials, you can fix the magnet to shaft without using adhesive by setting the shaft into the mold. (integral molding is possible). On integral molding, the concentric design of the mold are applied. So using the integral molding, you can reduce the vibration of motor due to eccentricity, too.

Wellmax™-S3 product has a maximum magnetic energy of 80kJ/m3(10MGOe) to 111kJ/m3(14 MGOe). Wellmax™-S5 product has a maximum magnetic energy of 135kJ/m3(16MGOe) to 143kJ/m3(18 MGOe). So these material has capability to deliver performance, superior to that of NdFeB compressed isotropic bonded magnets. And then you expect to enhance the properties of the motor with integral molding and reduce the cost and manual handlings.

In particular, Wellmax™-S3F product contains carbon fiber to reduce thermal expansion and shrinkage, and are effective in suppressing cracks and other phenomena even when the heat changes rapidly.

Wellmax™-S3/S4/S5 can reduce the motor weight because the specific gravity of magnet is about 4.1-4.9 that is less than about 5.9-6.3 of NdFeB compressed isotropic molded magnet. In addition, the magnet produced with them has high electrical resistance than NdFeB compressed magnets and sintered magnets, so you expect to reduce the temperature rise of the motor due to eddy current reduction.

(Contact us for details.)

Features realized by Wellmax™ can be applied in other fields as well; such as a function to “prevent” defective operation and vibration by integral molding, “prevent” temperature rise by using fewer magnet powders, and “reduce” the costs such as labor costs and disposal costs on defective products.

Do you try to realize your creations and ideas with our Wellmax™?

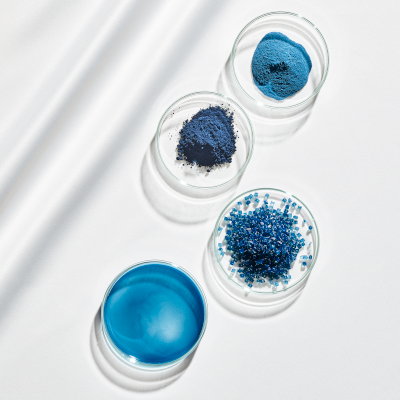

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PA magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

Ready to get started? Contact us to talk about your requirements.

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)