Near-Infrared Absorbing Materials

閉じる

Search

Secures oxidation resistance through structure of film formation by Ni. Exhibits high resistance to solder reflow process.

Learn more

Allows for circuit formation at temperatures that flexible substrates like polyimide can withstand, achieving particularly high printing adhesion.

Learn more

Arrange the amount of copper powder addition allows for printing support from thin to thick films.

Learn more

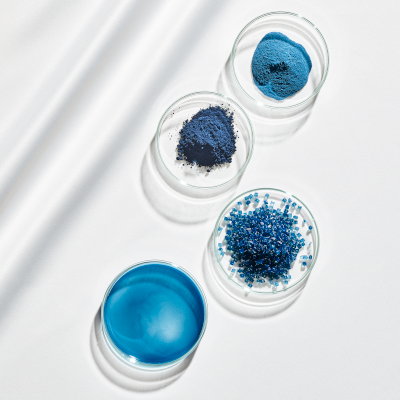

Copper Powder-Added Cu-Ni Complex Ink is a conductive material for printed electronics based on a Structure of oxidation-resistant film formation with Ni. Printed electronics is a next-generation technology that forms electronic circuits by printing metal films only where needed. Conductive materials for printed electronics currently on the market include inks using silver nanoparticles and copper nanoparticles; however, these materials are expensive, which has been a bottleneck in their market deployment and limited to specific applications. Furthermore, the nano-sized metal particles present challenges in terms of reliability like oxidation resistance and is difficult to made to apply high current circuit design due to thin electrode thickness. As a solution to these problems, by combining Sumitomo Metal Mining's fine copper powder, which can sinter at low temperatures like around 200℃, and precipitate copper from complexes, with ink that forms a complex where nickel, resistant to oxidation, covers the copper surface, it is possible to achieve ink film thicknesses more than three times that of typical conductive inks, enabling the development of conductive materials that can be applied to the development of devices with large areas and high currents.

Material:Fine Copper Powders

For conductive material as Printed Electronics

“Metal complex ink that forms the basis of Copper Powder-Added Cu-Ni Complex Ink”

Printed electronics, a technology that applies conductive ink to substrates to form circuit patterns, is expected to be a key technology in realizing an IoT society. The general electronic circuit formation technology (subtractive) involves removing (etching) unwanted parts from metal materials formed on the entire substrate, which poses challenges in material and energy consumption.

In contrast, printed electronics is an additive process that applies conductive ink only where needed and is expected to reduce usage, environmental impact, and production costs. Additionally, production efficiency can be enhanced using the Roll-to-Roll method, which feeds flexible substrates through devices. It enables the creation of thin, lightweight, and flexible electronic devices, making it applicable to a wide range of industries, including industrial uses such as solar cells, consumer electronics such as wearable devices, sensor devices, and aviation, automotive, healthcare, and home appliances with applications such as Radio Frequency Identification (RFID) tags.

Sumitomo Metal Mining’s dialogue content “”X-TALK”” invites guests from inside and outside the company to introduce them in a dialogue format. Please also see the article on the future prospects of printed electronics with a professor from the National Institute for Materials Science (NIMS), which has the core technology of this material.

X-TALK:The Future Prospect of Printed Electronics

It is typically made from a solution containing complexes of copper and nickel. Fine copper powder developed by Sumitomo Metal Mining is added to this solution and adjusted to the appropriate viscosity for production and produces a conductive ink.

For a more detailed process, please see the downloadable document.

Documents:Copper hybrid ink

Copper Powder-Added Cu-Ni Complex Ink has high conductivity and cost advantages, making it particularly suitable for applications that use large areas and quantities of materials. It can also be applied to compact devices due to its adjustable thickness, supporting printing from thin to thick films and contributing to the creation of the printed electronics market.

It is primarily designed for screen printing. We are also considering its application to gravure offset printing to accommodate fine wiring and complex shapes. We can also modify the design to suit the printing method, so please feel free to consult us.

Since the use of this material varies depending on our technical know-how about processing conditions, we are considering producing prototype samples according to your requested circuit patterns during the development stage. We will support you as your development progresses.

In addition, we can form electrodes with high adhesion by utilizing our knowledge of pre-treatment technology cultivated through copper polyimide substrate manufacturing.

(Example) With 100-micrometer-wide wiring, the thickness is more than 30 micrometers, which is more than three times thicker than the conventional 10 micrometers thickness of metal complex ink with no copper powder added.

For conductive material as Printed Electronics

Ready to get started? Contact us to talk about your requirements.