Near-Infrared Absorbing Materials

閉じる

Search

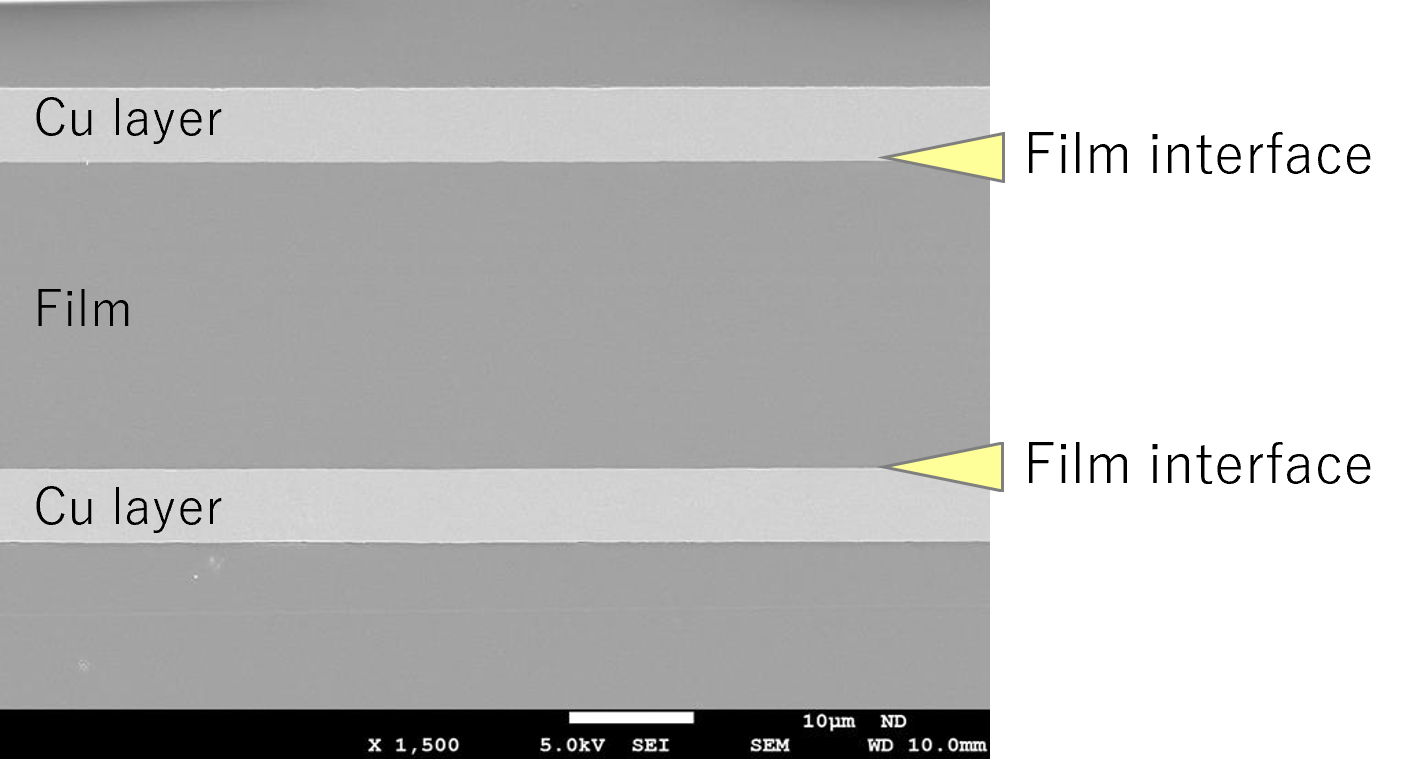

Flat film-metal interface realizes precise patterning and high insulation reliability of FPC.

Learn more

Thin and uniformed copper layer realizes precise patterning.

Learn more

Low spring-back and high folding endurance contribute to downsize electronic equipment.

Learn more

High transparency of base film maintained and enables to be applied for various “transparent products”.

Learn more

Flat film-metal interface of FCCL realizes low transmission loss at high-frequency.

Learn more

FCCL with thin copper layer and thin film contributes to downsize electronic devices.

Learn more

Sumitomo Metal Mining's FCCL (2-layer FCCL and transparent FCCL) is material fabricated by forming copper layer onto various organic resin films, such as polyimide films or transparent films. Flat film-metal interface and thin, uniformed copper thickness enable to process fine-pitch FPC. Wanted thickness of copper layer can be selected from 0.1μm to 9μm, and suited for subtractive process or semi-additive process(SAP,MSAP). Especially for SAP or MSAP, thin polyimide film of 12.5µm can be applied to achieve thinner and higher integrated devices. SMM transparent FCCL maintains original transparency of base film after processing FPC. As base film for transparent FCCL, PET film, colorless polyimide film having heat resistance, COP(cyclo olefin polymer) film having high transparency and low transmission loss or other various films can be applied. They should be suitable to the application of transparent displays, transparent FPC, transparent antennas, and transparent heaters. FCCL applying resin film is expected to be a substitute for copper foil as thinner, lighter and more flexible material.

S’PERFLEX

You can select FCCL with various films and wanted thickness of copper lSingle-sided (copper/film)

Double-sided (copper/film/copper)ayer. Please contact us for detailed specifications.

| Film | Copper layer | Shape |

|---|---|---|

| Polyimide film Transparent films, etc. |

Single-sided (copper/film) Double-sided (copper/film/copper) Standard thickness 0.3 μm, 2 μm, 8 μm (available down to 0.1μm as option, please contact us) |

Roll type, (for width or length, please contact us) |

SMM FCCL is mainly used as material to fabricate substrates for mounting driver IC in LCDs and organic EL displays, and are used in TVs, monitors, mobile PC, smart phones, and tablets. In future, they are expected to be used in electronic paper and monitors inside automobiles.

Transparent FCCL applying transparent films can be used for transparent displays and transparent FPC, transparent antennae, and transparent heaters.

FCCL can be used as materials for patterning various electric circuits.

The thickness of the copper layer can be selected to match processing method. For example, copper layer of 0.1μm to 4μm for semi-additive process (SAP,MSAP), 6μm to 8μm for subtractive process and 2μm to 5μm for subtractive process with panel-plated through-hole.

Transparent FCCL applying transparent films can be used to fabricate transparent FPC without impairing visibility.

SMM FCCL adopts Roll to Roll process to suit mass production.

SMM FCCL can be a substitute for copper foil in parts to be thinner, lighter and more flexible.

Used as a base material to form electric circuits for devices. For example, SMM FCCL has been used as a base-material to fabricate substrate for mounting a driver IC to control TVs, monitors, mobile PC, smart phones, and tablets displays.

One of the main features of SMM FCCL is flat film-metal interface. Flat interface can solve various problems. For example, if a fine circuit cannot be formed due to uneven shape of patterning, FCCL with flat interface can help to improve linearity in shape and uniformity in width. Further improvements expected as follows.

(Examples)

SMM FCCL does not contain adhesive.

SMM FCCL is fabricated by forming copper layer directly on various organic resin films using advanced metallizing technology. You can select copper layers freely in thickness and film types to suit your requirements.

(Combination example)

Used as materials to fabricate FPC with SAP,MSAP and subtractive processes. Transparent FCCL with thin copper layer can be used to form thin and narrow patterning not to impair visibility. Besides, FCCL can be a substitute of copper foil for lightweight and flexibility.

S’PERFLEX

Ready to get started? Contact us to talk about your requirements.