Magnetic

Materials

閉じる

Search

=Customer’s requirements =

“Isotropic NdFeB (neodymium iron boron) bonded magnets are used, but the magnetic force is not enough…”

“I want to use existing facilities to increase the magnetic force of the bonded magnet a little more…”

“Maintaining the magnetic force of the current bonded magnet to make it smaller…”

Generally, the method of mixing powder with different particle sizes is known as a method of increasing the density. This process can be applied to bonded magnets. Although, there are some problems such as;

・the concerns about oxidization,

・there are no fine particles for NdFeB bonded magnets,

・it is expensive,

・powder for ferrite bonded magnets is as fine and cheap as several micrometers, but it cannot be used well even if mixed because the magnetic force is too different compared with powder for NdFeB bonded magnets.

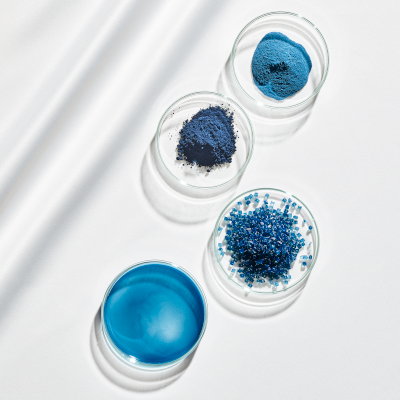

Sumitomo Metal Mining’s Wellmax™-S1 product (SmFeN magnet powder) has a magnetic force equivalent to that of magnet powder for NdFeB bonded magnets and a magnet powder with an average particle size of 2 to 3 micrometers that is sufficiently finer than that of magnet powder for NdFeB bonded magnets (about 100 micrometers).

Wellmax™-S1 is an easy-to-handle powder with surface inactivated by a special treatment, although it is a rare-earth magnetic powder that easily oxidizes. It is also a magnet material that does not use neodymium (Nd) or cobalt (Co) and has low price fluctuations. It can be used not only in combination with anisotropic NdFeB magnet powder, but also in combination with isotropic NdFeB magnet powder, etc.

Various combinations are expected not only to increase the density but also to increase the coercive force and reduce the cost.

【Particle size distribution】

Wellmax™ magnet materials not only increase density but also reduce the risk of supplying materials.

Wellmax™-S1 (SmFeN magnet powder) is a magnet material that uses surplus Sm (samarium) among rare earth elements, thus reducing the risk of supplying materials.

Compared with NdFeB magnetic powder, it causes less rust and die wear.

For details, contact SMM once.

Why not realize your imagination with “Wellmax™”?

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PA magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

Ready to get started? Contact us to talk about your requirements.

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)