Reduce

Production requirements

閉じる

Search

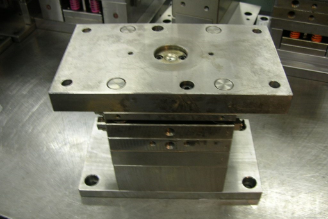

Fine grain provides abrasion prevention for magnetic mold.

Learn more

SmFeN magnet material is less likely to rust than NdFeB magnet material and has the same or higher magnetic force

Learn more

More magnetic force than ferrite magnets.

Learn more

Use of the surplus element

Learn more

Reduced man-hours and costs by integrally molding with the yoke and shaft without human assembly

Learn more

To higher density and enhancer magnetic force by pack more magnetic powder with bimodal distribution

Learn more

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PA magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

| Product name | Magnetic Powder | Binder | Max. Magnetic Energy Product (kJ/m3(MGOe) Features | Characteristics |

| S1 | SmFeN

(Anisotropy) |

(Magnetic Powder) | 286~310(36~39) |

・Average particle size 2~3μm diameter SFN fine particles

|

| S3 | PA12 | 80~111(10~14) |

|

|

| S4 | SmFeN+Ferrite

(Anisotropy) |

PA12 | 24~56(3~7) |

|

| S5 | SmFeN+NdFeB

(Anisotropy) |

PA12 | 135~143(17~18) |

|

| S5P | PPS | 80~103(10~13) |

|

Registration form is below to download product catalogues.

Wellmax™ SmFeN magnetic materials have more than 20 years of experience in familiar electric appliances such as air conditioners and washing machines. In recent years, there has been an increase in the use of motors in various applications, including automotive motors.

We provide magnetic field analysis simulations for magnet mold design so that our customers can effectively use anisotropic magnets and ensure that their products meet the required performance. We also provide advice on mold configurations to support the realization of our customers’ products. Examples include the use of magnetic and non-magnetic materials, magnet-related equipment (molding machines, magnetizing power supplies, etc.), and molding conditions.

Support for mold design with our simulation of magnetic field analysis

Main applications include SmCo (samarium-cobalt) magnets. SmCo magnets are expensive, but they are used continuously in sensors and other applications due to their excellent thermal stability at high temperatures.

As rare-earth is called “rare-earth,” it is often thought that the reserves are small, but as far as we know, there are over 100 million tons. In recent years, we have found that the seafloor near Japan has reserves equivalent to hundreds of years worth of world demand.

It is used in all kinds of appliances, including motors, generators, and magnetic disks. Because of its strong magnetic force, its use is increasing in products that require smaller size, lighter weight, and higher efficiency.

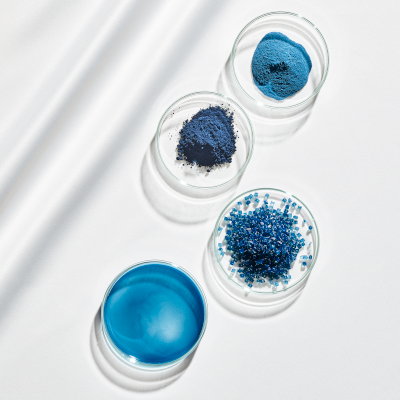

1. There are SmFeN(SFN) magnet powder, injection-molded material mixed with 12 nylon (PA12) using SFN magnet powder and ferrite magnet powder, and injection molding materials mixed SFN magnet powder and 12 nylon (PA12). These are neodymium-free products. Injection molding materials are available in 1 to 2MGOe increments with maximum magnetic energy product of 23~111kJ/3 (3 to 14MGOe).

In addition, there are injection molding materials containing anisotropic neodymium iron boron magnet powder and SFN magnet powder, although they contain neodymium. They are injection molding materials having a maximum energy product of 135-143kJ/m3 (17-18MGOe) for PA12 resin based products and 95~103kJ/m3 (11~12MGOe) for polyphenylen sulfide (PPS) resin based products.

2. In addition to SFN materials, we also manufacture and sell injection molding materials using isotropic neodymium magnet powder by in-house kneading.

| Type | Magnet Powder | Directional Property | Binder Resin | Maximum Energy Product※ | Characteristics |

|---|---|---|---|---|---|

| S1 | SmFeN | Anisotropic | (Magnet Powder) | 286~310(36~39) | SFN fine particles with an average particle size of 2 to 3μm. Category 2 hazardous materials (flammable solids) |

| S3 | PA12 | 80~111(10~14) | Magnetic compound of SmFeN alone. By changing the blending ratio of the magnet powder and the binder resin, Optimal magnetic properties can be selected. | ||

| S4 | SmFeN+Ferrite | PA12 | 24~56(3~7) | This is a hybrid compound with “SmFeN + ferrite. Higher magnetic properties than ferrite injection make use of the advantages of injection molding. | |

| S5 | SmFeN+NdFeB | PA12 | 135~143(17~18) | This is a hybrid compound with “SmFeN + anisotropic NdFeB. It exhibits higher magnetic properties than S3. | |

| S5P | PPS | 80~103(10~13) | This is a hybrid compound with “SmFeN + anisotropic NdFeB. PPS resin with high heat resistance is used as a binder. |

※kJ/m3(MGOe)

We support our customer's product development by using magnetic field analysis software,

aiming to shorten development time and reduce cost.

Bonded Magnet Materials of SMM

Anisotropic SmFeN (Samarium-Iron-Nitrogen) magnet powder

Anisotoripic SmFeN (Samarium-Iron-Nitrogen) PA12 magnet pellet for injection molding

Anisotropic SmFeN (Samarium-Iron-Nitrogen) mixed Ferrite PA12 magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PA magnet pellet for injection molding

Anisotropic NdFeB mixed SmFeN PPS magnet pellet for injection molding

Ready to get started? Contact us to talk about your requirements.

Reduce

Production requirements

Enhance

Cost increase

Reduce

Raw material risk

Prevent

Rust

Prevent

Wear

Enhance

Magnetic force

![[Wet-chemical synthesized metal powder] Ultra-fine nickel powders](https://crossmining.smm.co.jp/wp-content/uploads/m_np.webp)